This site uses cookies. Continuing to browse means you agree to our use of cookies.Cookies and Privacy Policy>![]()

This site uses cookies. Continuing to browse means you agree to our use of cookies.Cookies and Privacy Policy>![]()

Product dynamics of precision computer room air conditioning, UPS power supply, cold and warm dry wet, etc

Precision air conditioning, UPS power supply and other data center room products

Repair and maintenance of computer room air conditioning and precision air conditioning

Heat Exchange Imbalance Principle

Frosting occurs when evaporator heat absorption < refrigerant evaporation rate, causing incomplete vaporization and liquid refrigerant return to the compressor

Critical indicator: Suction superheat should be maintained at 5-8°C; values below 2°C indicate frosting risk

Fault Tree Diagram

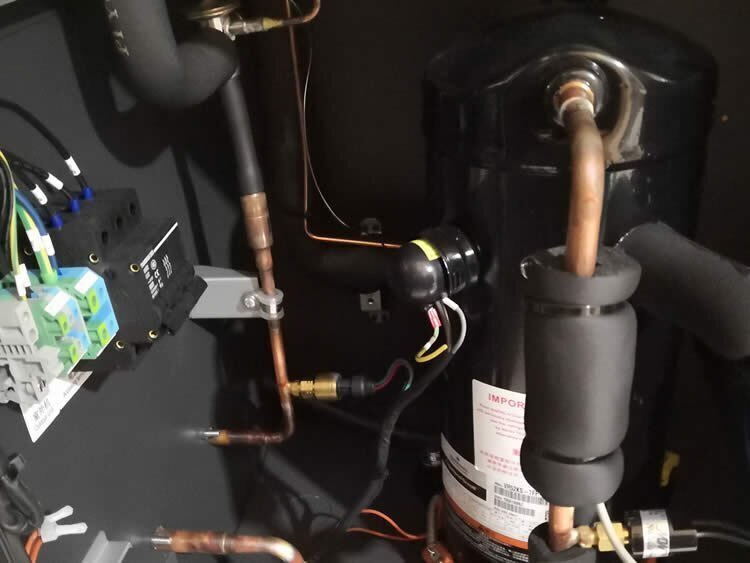

Compressor Frosting

Refrigerant Cycle Abnormality

Airside Malfunction

Control System Failure

Refrigerant Shortage

Expansion Valve Failure

Filter Clogging

Fan Malfunction

Sensor Drift

PLC Logic Error

| Cause Category | Test Parameters | Professional Tools | Risk Level |

|---|---|---|---|

| Refrigerant Shortage | Low high/low pressures, bubbles in sight glass | Electronic scale for refrigerant recovery | ★★★★ |

| Expansion Valve Stuck | Uneven frosting, abnormal opening feedback | Valve disassembly + coil resistance test | ★★★★ |

| Evaporator Fouling | Fin pressure drop >30Pa | Particle counter + endoscope | ★★★ |

| Fan Speed Reduction | Measured airflow <80% rated | Anemometer + current clamp | ★★★ |

| Filter-Drier Clog | Temperature difference >3°C | Infrared thermal imager | ★★ |

| Humidity Sensor Fail | RH deviation >5% | Saturated salt solution calibration | ★★ |

Step 1: Emergency Shutdown

Cut power immediately to prevent liquid slugging damage

Apply warm towels to frosted areas (NEVER pour hot water directly)

Step 2: Systematic Troubleshooting

Refrigerant System Check

Normal range (R407C): High 1.5-2.0MPa, Low 0.4-0.6MPa

Use manifold gauges:

Refrigerant purity test: Replace if moisture >100ppm

Expansion Valve Adjustment

Theoretical Opening = (Current SH ÷ Design SH) × Factory Setting

Example: Design SH 5°C, actual 2°C, factory 4 turns → Adjust to (5/2)×4=10 turns

Airside Maintenance

Replace if bearing clearance >0.15mm

Replace capacitor if capacity deviation >±10%

Use pH7-8 neutral detergent

Water pressure <0.3MPa to prevent fin damage

Clean evaporator:

Fan inspection:

Step 3: Verification Test

Step-load test:

| Load Stage | Duration | Permissible Frosting |

|---|---|---|

| 25% | 30min | Light condensation at base |

| 50% | 1h | No frost on suction line |

| 100% | 2h | Stable superheat at 5±1°C |

Smart Monitoring

Primary (SH <3°C): Auto-increase valve opening 10%

Critical (SH <1°C): Forced shutdown

Install real-time superheat monitor (e.g., Danfoss AK-CC550)

Set two-tier alerts:

Optimized Maintenance Intervals

| Component | Standard Cycle | High-Dust Cycle |

|---|---|---|

| Air Filter | 1 month | 15 days |

| Evaporator Clean | 3 months | 1 month |

| Refrigerant Moisture Test | 2 years | 1 year |

Retrofit Recommendations

Install suction accumulator (intercepts >98% liquid refrigerant)

Upgrade to electronic expansion valve (e.g., Emerson EX5 series, ±0.5°C accuracy)

Case: Cyclic Frosting in Variable-Speed Compressor

Symptom:

Frosting at low frequency (<30Hz), resolves at high frequency

Root Cause:

Oil return design flaw during low-speed operation

Solution:

Switch to higher viscosity oil (POE→PVE)

Install oil level balancer

Adjust parameters: Minimum speed ≥35Hz

Prohibited Actions

Starting frosted compressor (valve plate fracture risk)

Open-flame thawing (may ignite insulation)

Essential PPE

Safety goggles and cryogenic gloves for refrigerant handling

Confirm capacitor discharge (<50V) before electrical work

Note: For R32 flammable refrigerant systems, explosion-proof equipment and adequate ventilation are mandatory.